GIEBEL Sense® - for monitoring the loading status.

Simple screw-on solution

No modifications to the system required

Perfect for scheduling maintenance work

Analog and modbus RTU variant - giving you outputs at loading states of 0%, 50%, 75% and 100%

BUY ONLINE HOW IT WORKS INSTALLATION TECHNICAL DATA DOWNLOADS

Reminds you when it is time to change the adsorber.

Keeping an eye on the loading status of adsorbers, ordering replacements in good time and scheduling maintenance appointments with pinpoint accuracy can become complicated as the number of adsorbers increases or if they are installed in hard-to-reach or rarely visited locations.

This is where sensors can help. They inform you of the loading status in analog form or via Modbus RTU.

How it works.

The desiccant absorbs moisture from the air flowing through it and reduces the relative humidity inside an adsorber. The more moisture it has already absorbed, the less water it can extract from the air flowing through. The %RH value of the air surrounding the desiccant is therefore directly related to the loading state of an adsorber.

The sensor measures this value and can thus provide information about the loading state.

Installation of a sensor.

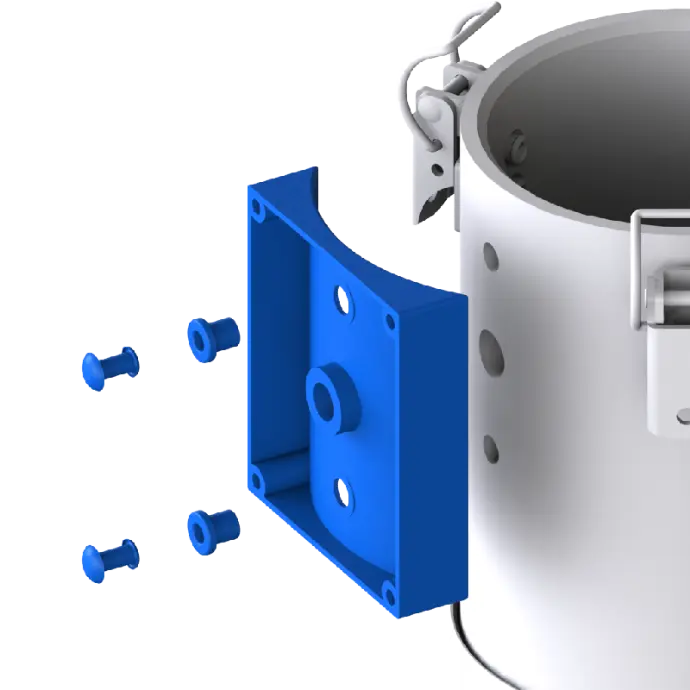

Step 1: Carrier plate

If you order the GIEBEL Sense® with a new adsorber, it will be delivered pre-assembled. If you want to retrofit a sensor, drill holes in the adsorber according to the drilling template and attach the carrier plate.

Step 2: Membrane sticker

Apply the PTFE membrane sticker to the inside of the pipe over the hole in the center.

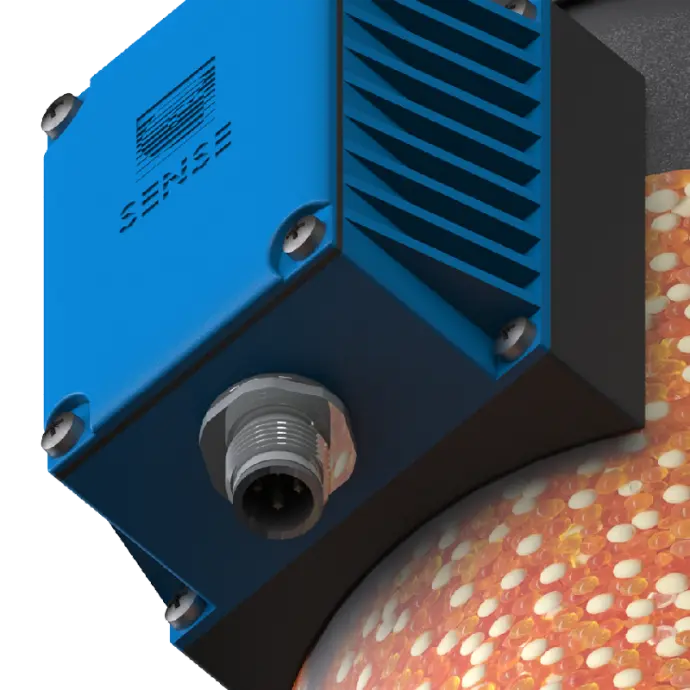

Step 3: Sensor

Attach the sensor and tighten the screws.